Cotton Warehouse Fires - The Arosa Solution:

Fires in cotton bale storage warehouses (godowns) occur frequently around the world. These devastating fires start from a single spark that is created by forklift blades, sparking of electrical equipment, and even from a spark inside the bale as it arrives from the cotton gin (known as a “Hot Bale”).

Once the true fire begins, the only effective way to extinguish the burning bales is to completely drench them with water for hours and if possible remove them from the warehouse into the yard – a dangerous operation for all involved.

Cotton bale warehouses are normally open only when the bales are delivered, then the large doors are closed and locked until the bales are required by the spinning department. It is during this closed period that a spark can smoulder for hours or days before erupting into an uncontrollable fire – these early stages are the time when the Arosa System is doing its job to actively detect particles of combustion, even before the fire can begin.

Experience has proven that traditional spot smoke detectors do not work well in these harsh environments. Cotton dust, humidity and forklift smoke contaminate traditional smoke detectors and trigger false alarms or cause them to fail, usually without any notice or indication.

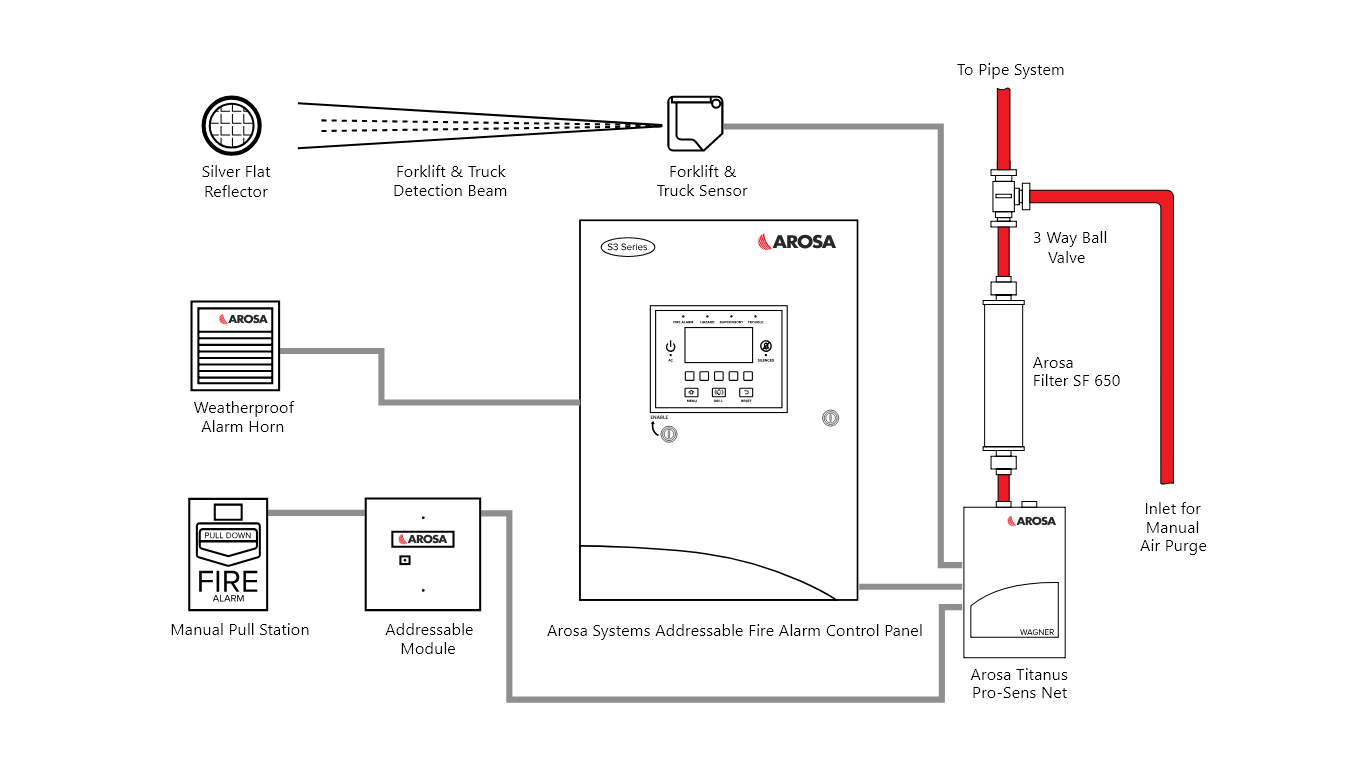

Aro:Smoke Early Warning Smoke Detection

High sensitivity smoke detection – senses the smoke of a single cotton bale

Quick detection of particles of combustion, more than 200 times more sensitive than traditional spot smoke detection.

Extra-large warehouse coverage

Up to 6,000 square meters (65,000 ft. sq.) by each system.

Multiple sensitivity settings

Allows fine tuning of the smoke detection system and can be modified in the field as conditions change.

No False Alarms – Smart Sensing

System identifies when forklifts or delivery trucks are operating in the building and reduces sensitivity to eliminate false alarms from diesel smoke